Engine Build - Gen IV LS 6.2L LS3 Supercharged

Project Overview

This 6.2L LS3 build was developed to replace the LS6 in KTR’s 2002 Corvette Z06, with future plans for forced induction. Starting with a brand-new GM LS3 block, the engine was sent to Golen Engine for machining, forged internals, and a 24x crankshaft reluctor conversion—allowing the Gen 4 LS3 to communicate seamlessly with the factory ECM. The assembly was completed in-house at KTR Performance and initially installed with a naturally aspirated cam before being reconfigured for boost and paired with a Magnuson Heartbeat Supercharger Kit.

Engine Specs: 6.2L LS3

- Block:

- Brand-new GM LS3 (machined by Golen Engine)

- Crank:

- Stock GM with 24x reluctor conversion

- Pistons:

- Wiseco Forged

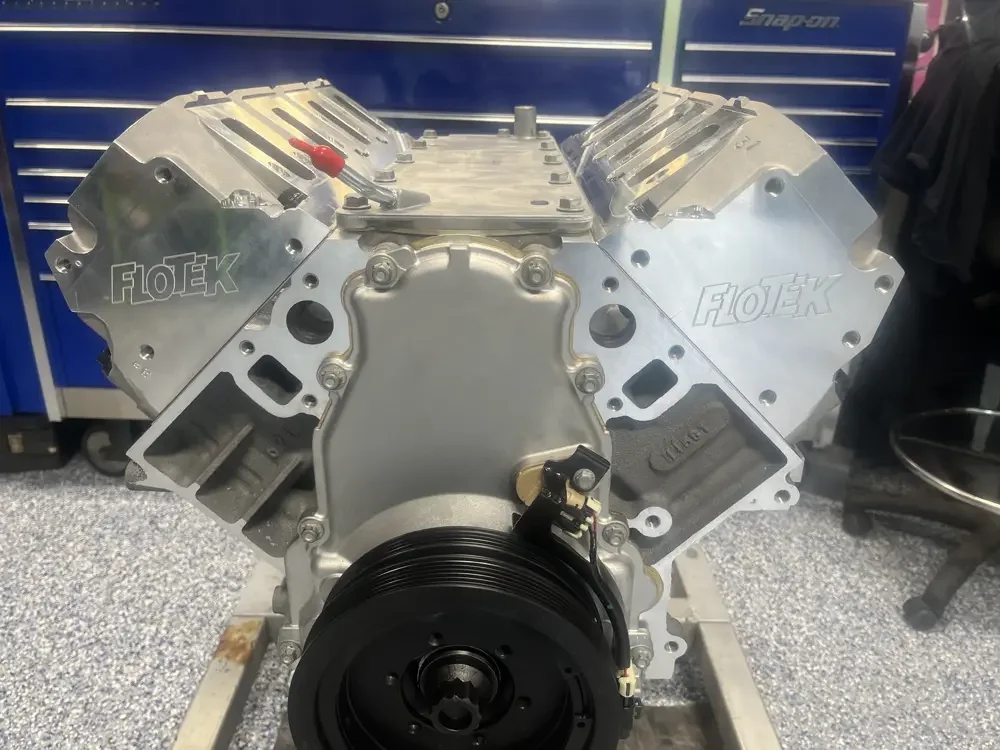

- Cylinder Heads:

- Flotek

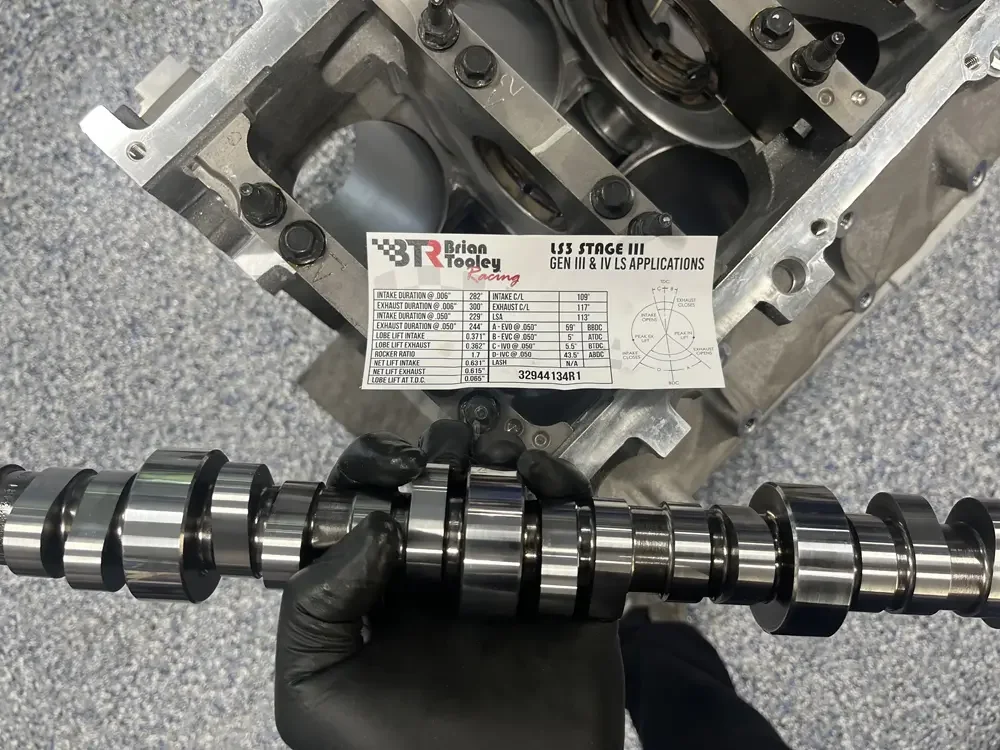

- Camshaft:

- Lingenfelter Performane Engineering GT9

- Induction:

- Magnuson Heartbeat Supercharger Kit

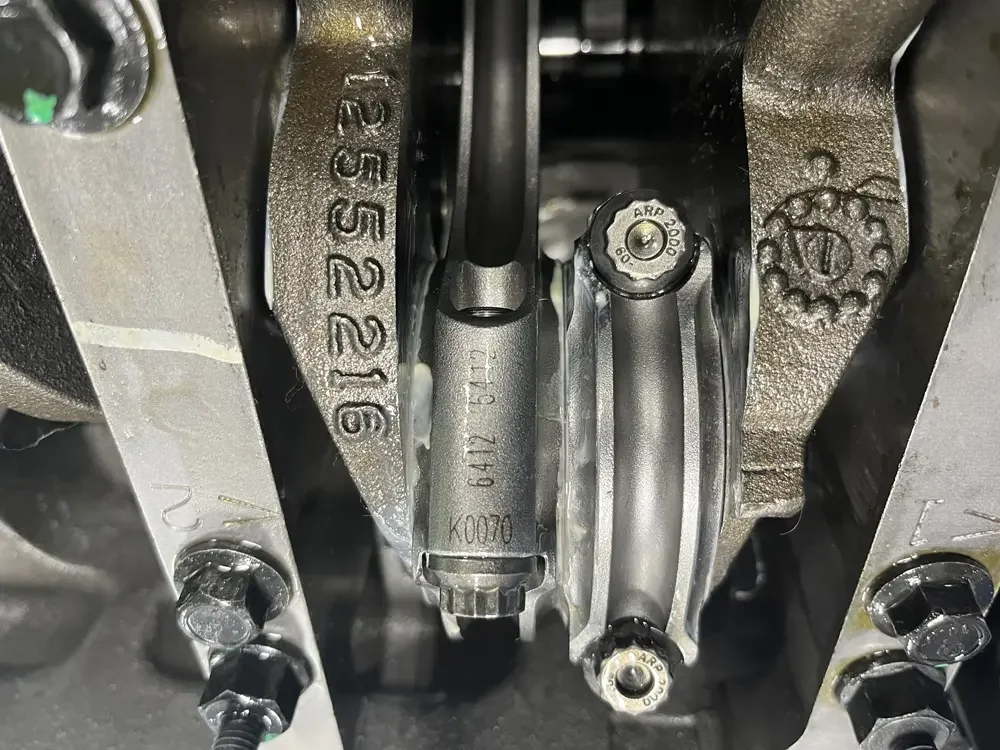

- Rods:

- K1 Forged

- Est. HP at Flywheel:

- TBD (post calibration)

Build Details

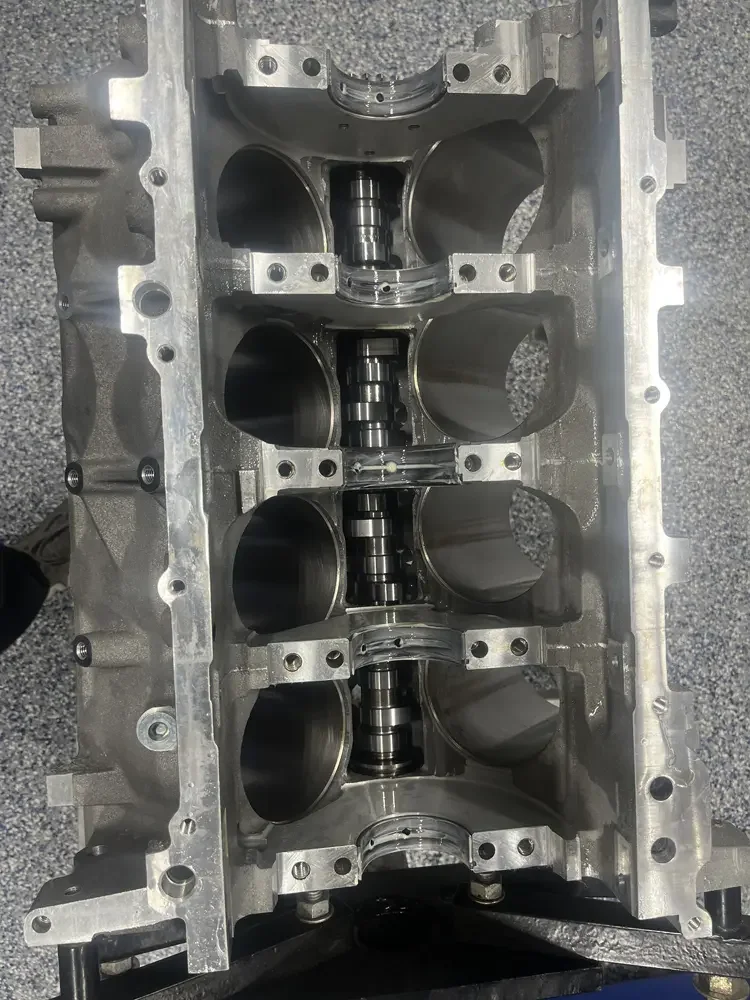

Short Block: The foundation is a brand-new GM LS3 block machined by Golen Engine for forged components. The crankshaft shaft was fitted with a 24x crankshaft reluctor wheel to ensure compatibility with the factory C5 ECM Forged internals were used throughout for strength and reliability under boost.

Camshaft & Valvetrain: The engine was initially assembled with a naturally aspirated camshaft profile for baseline testing. Once ready for boost, it was reconfigured with a boost-specific cam grind designed to complement the Magnuson Heartbeat system.

Induction & Management: Forced induction is handled by a Magnuson Heartbeat Supercharger Kit, chosen for its OEM fitment and efficient intercooling design. The factory ECM remains in use, tuned to support the 24x conversion and supercharged setup.

Assembly & Integration: All final assembly was performed in-house at KTR. The completed engine was installed into the 2002 Corvette Z06, creating a modern, high-output LS platform with OEM drivability and strong potential for further tuning.

Dyno / Notes: Final tuning and dyno testing will be performed on KTR’s Mainline ProHub Dyno after break-in and calibration. Estimated figures to be provided after final testing.